Aluminum casting is supporting industrial improvements in this expert blog post.

Comprehending Sand Casting vs. Pass away Spreading: Which Aluminum Factory Method Fits Your Job?

When contrasting sand casting and pass away casting for light weight aluminum projects, several critical aspects come into play. Each technique has distinct qualities that satisfy various manufacturing needs. Comprehending these distinctions can significantly impact job end results. As one considers elements like manufacturing quantity and design complexity, the decision ends up being progressively nuanced. Which technique will inevitably align finest with certain task requirements? The solution may not be as simple as it appears.

Overview of Sand Casting

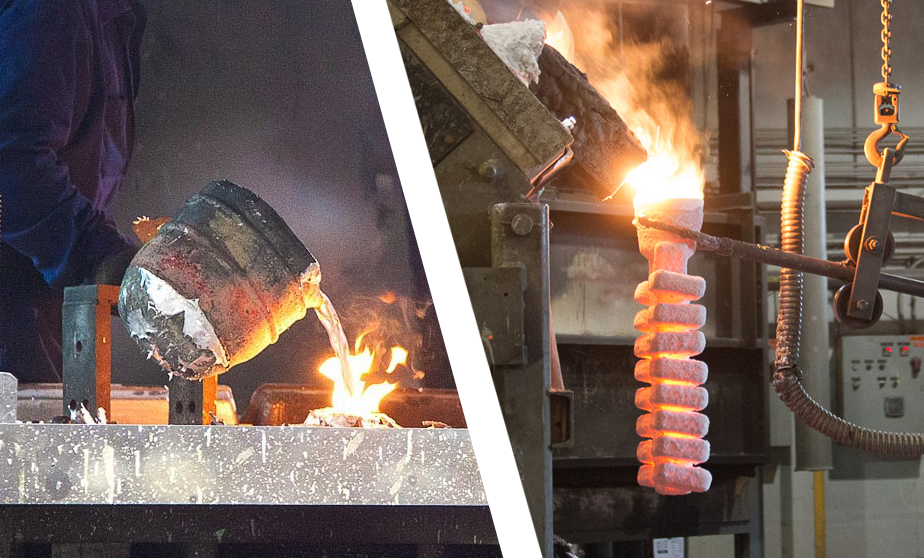

Sand casting is an extensively made use of metal casting process that utilizes sand as the main mold product. This approach is notable for its versatility, permitting the production of complicated forms and large components. The process begins with creating a mold by compacting sand around a pattern, typically constructed from steel or plastic. As soon as the mold and mildew is ready, molten metal is poured right into the dental caries and permitted to strengthen. After cooling down, the sand mold and mildew is damaged away to reveal the final casting.

One of the significant benefits of sand spreading is its cost-effectiveness, specifically for reduced to tool production quantities. It suits a selection of steels, including aluminum and iron, making it suitable for varied applications. In addition, sand spreading can be adapted for different shapes and sizes, making it possible for manufacturers to meet specific task needs effectively. This adaptability makes it a preferred selection in sectors such as vehicle, aerospace, and building.

Review of Pass Away Casting

Secret Benefits of Sand Casting

Among the primary advantages of sand spreading hinges on its flexibility and cost-effectiveness. This method fits a variety of products, including different light weight aluminum alloys, enabling diverse applications in various industries. The simpleness of the sand casting procedure makes it possible for producers to create intricate shapes and sizes without the need for expensive machining, making it especially helpful for reduced to tool manufacturing quantities.

The use of sand as a mold material provides outstanding thermal residential properties, promoting the spreading of elaborate styles with precision. The ability to conveniently create new molds for different jobs additionally improves its adaptability. Additionally, sand casting needs very little in advance investment in tooling compared to other casting informative post methods, making it available for smaller enterprises. These benefits jointly place sand spreading as a favored option for many makers seeking flexibility and economic efficiency in their manufacturing processes.

Key Advantages of Pass Away Casting

When comparing spreading techniques, die casting deals distinctive advantages that deal with high-volume manufacturing requirements and exact engineering requirements. This approach allows the development of complicated geometries with tight resistances, which is essential for sectors needing precise specifications, such as automotive and aerospace (Aluminum Foundry). Pass away casting additionally results in exceptional surface coatings, minimizing the requirement for comprehensive post-processing

Furthermore, the procedure is very effective; molten steel is infused into mold and mildews at high stress, enabling quick cycle times and increased manufacturing rates. This performance converts into price financial savings, making die casting an affordable option for large-scale production. In enhancement, you could try these out the sturdiness of parts created via die spreading ensures their long life and dependability in numerous applications. Eventually, these benefits position die spreading as a leading alternative for projects concentrating on top quality, efficiency, and accuracy in high-volume manufacturing scenarios.

Choosing the Right Approach for Your Project

How can a job supervisor identify the most suitable casting technique for their details demands? The decision in between sand spreading and die casting depend upon several key variables. Initially, the job supervisor have to assess the required volume of parts; die casting is a lot more efficient for high-volume production, while sand casting fits low to moderate quantities. Next off, they ought to take into consideration the complexity of the design. Elaborate geometries commonly favor die casting as a result of its accuracy abilities, whereas sand spreading enables better versatility in style adjustments.

Material residential properties likewise play a critical role, as die spreading commonly generates more powerful components with premium surface finishes. Cost effects, consisting of tooling and material expenditures, need to be evaluated; sand casting often offers reduced preliminary costs however can be much less effective in automation. Eventually, the project supervisor must weigh these aspects against job timelines, budget restrictions, and quality requirements to choose the suitable approach that lines up with the project's objectives.

Frequently Asked Inquiries

What Sorts Of Aluminum Alloys Appropriate for Sand and Pass Away Casting?

Various light weight aluminum alloys are suitable for sand and pass away spreading, including 356, 319, and 413 alloys. These selections are preferred for their exceptional castability, link mechanical buildings, and suitability for diverse applications in production.

How Do Manufacturing Costs Contrast Between Sand Casting and Pass Away Casting?

Manufacturing prices for sand casting are usually lower due to less complex products and arrangements. In contrast, die spreading entails higher first costs from tooling yet provides expense financial savings through automation, making it more economical at larger ranges.

Can Both Methods Create Facility Geometries?

What Is the Normal Preparation for every Casting Approach?

Normally, sand casting preparation range from one to 3 weeks, affected by complexity and volume. On the other hand, die casting generally provides much faster production, with preparations frequently in between one to 2 weeks, depending on style requirements.

Exactly How Do Ecological Elements Impact Casting Top Quality?

Environmental aspects, consisting of temperature, dirt, and moisture degrees, greatly effect casting top quality. Variants can result in issues such as porosity or surface imperfections, eventually impacting the mechanical homes and efficiency of the final cast item.

When comparing sand casting and die casting for aluminum projects, a number of important variables come right into play (Aluminum Casting Company). Sand casting is a widely used metal casting process that employs sand as the primary mold product. Pass away casting is one more famous metal casting process that uses unique benefits contrasted to sand spreading. The job manager should evaluate the required volume of components; die casting is more reliable for high-volume manufacturing, while sand spreading fits low to modest quantities. Both sand spreading and die spreading can generate complicated geometries, though they accomplish this in different ways